Can Screws Be Used In Concrete Walls?

The essential element of any fixing application process is choosing the correct screw or fixing. And just like you can get screws specifically designed for fixing woods and plasterboard, you can also get screws specially for screwing into concrete. As you might expect, screwing into concrete requires a specialist type of fixing, so a screw for drilling into concrete isn’t known by any other name but a concrete screw.

A concrete screw is designed for heavy duty applications where you need to screw into concrete, masonry or brick. This is often when a building is being fabricated and fitted out and therefore requires high-level fixing of items such as ventilation, electrical trays and cabling or attaching steel structures, fixing sanitary fixtures also often requires screwing into concrete.

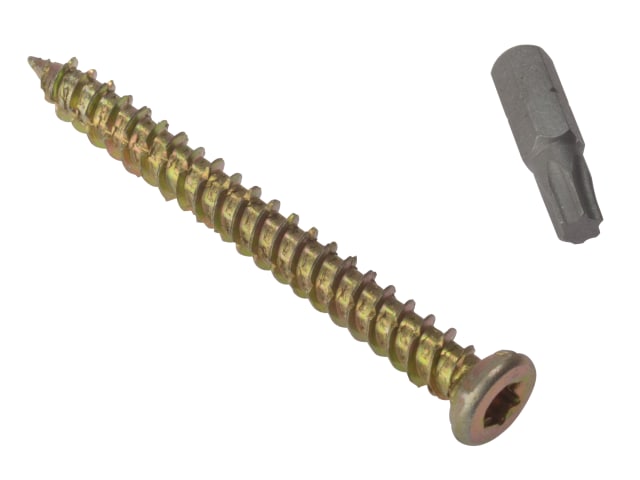

What does a concrete screw look like?

A concrete screw looks much like any other screw, but there are subtle elements of its design which make it particularly suitable for drilling into concrete. A concrete screw has a serrated cutting thread which is used to provide the requisite resistance when screwed into the concrete. For this reason a concrete screw doesn’t require a plug, instead you directly screw into a pre-drilled hole and the thread and the concrete material will combine to provide the resistance required.

There are different heads for concrete screws according to the type of application. Hex heads sometimes have an integrated washer for heavier loads, as the washer spreads out the load more evenly. A hex head will protrude the surface and stand proud of the fixture being fixed. A pan head provides a more flush finish and so is used more often when an aesthetic finish is required, because the screw head can’t be seen. Also common is a round head with a recess for the drill bit. This enables increased torque control, which is important because you do need to be careful not to overtighten a concrete screw.

How do I use a concrete screw?

You would use a hammer drill to make a drill hole in the surface you are working with, ie. concrete, masonry or brick. This breaks down the concrete sufficiently and you don’t then need a hammer to make the required hole. You then need to clean out the hole and remove any concrete dust. This is important to ensure you can apply sufficient torque in the screwing action. Once you have cleaned the drill hole out you can drive in the screw, being careful not to overtighten, although the torque required will vary depending on the nature of the application and the load you are securing. Remember that you don’t need a plug to screw into, you can screw directly into the concrete.

It is also important to note that you can remove a concrete screw. Many people make the mistake of assuming that because a concrete screw is for heavy duty applications, it is a permanent fixing. But if you need to re-position or remove a fixture, the concrete screw can be reversed out of its position quite easily.

How do I choose the right concrete screw?

There are four factors to consider when choosing the right concrete screw for your needs:

Weight capacity - What are the load requirements of the item you are fixing? Generally speaking a thicker screw will have more load capacity, but be careful that you don’t go too long in length.

Length - The concrete screws supplied by MB Direct range from 42mm in length to 202mm, and are therefore suitable for a wide range of applications. You need the screw to penetrate the fixture and sufficiently into the base material to provide the required load capacity.

Head type - Which head type – hex, pan or rounded – best suits the application method and the aesthetic needs of your application?

Material - Concrete screws are typically made from a corrosion-resistant material such as stainless steel, or a zinc yellow passivated coating. This is because concrete screws are often used externally and therefore need to be weather-resistant.